Welcome to Haynes Publishing Group

Haynes is a leading supplier of content, data and innovative workflow solutions for the automotive industry and motorists

For professionals

HaynesPro is an automotive data solutions and intelligent workflow provider which creates value within every branch of the automotive aftermarket. OATS is a leading source of lubricant recommendations for the oil and lubes industry, with partners in over 90 countries including some of the world’s major global petrochemical companies.

HaynesPro Homepage

From the moment HaynesPro was founded in 1995, the company has focused on delivering automotive data solutions in an electronic format to the European automotive aftermarket. It became a part of the Haynes Publishing Group in 2008 and has since developed to become the leading automotive data supplier in Europe. HaynesPro’s automotive data and workflow solutions are used by various branches of the automotive industry such as parts distributors, parts manufacturers, diagnostic equipment manufacturers, workshop chains and fleet operators.

In 2016 the professional segment of Haynes was strengthened by the acquisition of OATS Ltd, a leading supplier of oil & lubricants data and productivity solutions. OATS’ database of oil & lubricants covers motorcycles, cars, vans, trucks, agricultural and off-highway equipment. It is used by clients in over 90 countries, including some of the world’s best-known petrochemical brands.

In 2017, e3 Technical was acquired, a leading supplier of vehicle data in the UK. The company, which was subsequently renamed to HaynesPro UK, is a DVLA licence holder. With data feeds from the DVLA and other key automotive industry companies HaynesPro has built a highly accurate and granular UK vehicle database.

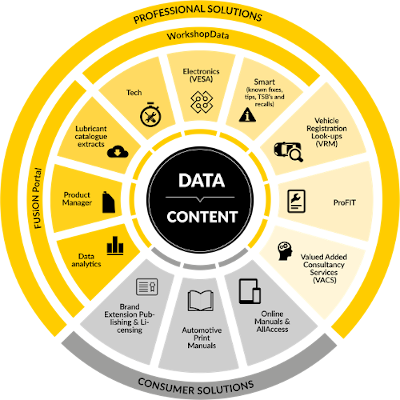

HaynesPro and OATS form the Haynes Professional Group, which delivers a range of data and workflow solutions, from technical data with step-by-step diagnostic data, highly accurate VRM and identification data, scalable vector graphics with embedded technology, global oil and lubricants data to bespoke data solutions. Haynes Professional enables its clients in the automotive aftermarket to create value with data products through innovation, integration, partnership and increased efficiency.”

For consumers

Haynes originates and delivers practical automotive repair and maintenance information to motorists and enthusiasts in both a print and digital format across the world. Haynes also publishes a range of brand extension titles covering a wide variety of subjects styled on the iconic Haynes Manual as well as a range of light-hearted factual titles published under the Bluffers branding.

Haynes Consumer

Signup to our mailing list

Receive updates for investors delivered straight to your inbox